How Data‑as‑a‑Service (DaaS) Helps Manufacturers Scale Smarter by Unlocking Existing Systems

1. What is DaaS and Why It Matters to Manufacturers

Data‑as‑a‑Service (DaaS) brings data from across systems like ERP, MES, CRM and spreadsheets into a managed, accessible platform for flexible reporting and analysis. Rather than buying new software, manufacturers can tap into live data, get trusted dashboards, and scale insights without heavy infrastructure. It’s a way to transform operational chaos into clarity.

2. The Common Data Catch-22 in Manufacturing

Mid-market manufacturers often face these challenges:

Blocked reporting due to manual spreadsheets

Disconnected systems that don’t speak with each other

Lack of trust in data accuracy

Reporting delays and poor decision-making

DaaS removes these obstacles by centralising data pipelines, standardising definitions, and delivering built-in governance, all through a flat-fee service.

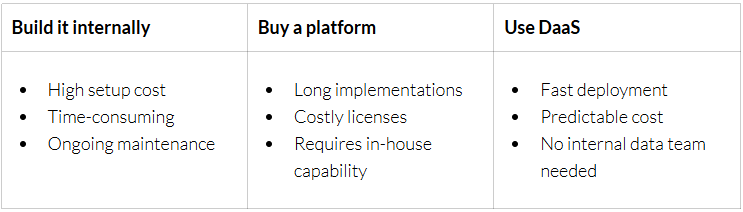

3. How DaaS Beats Build vs. Buy Decisions

With DaaS, manufacturers avoid brainstorming tools and tech. Instead, they focus on outcomes, real insights and action.

4. Operational Use Cases Where DaaS Wins

4.1 OEE & Downtime Visibility

Pull machine runtime from MES and breakdown logs

Automate OEE dashboard daily

Shift managers get immediate alerts when performance dips

4.2 Predictive Maintenance

Trend downtime triggers and compare against thresholds

Forecast failures before they happen

Reduce reactive fixes and cut maintenance costs

4.3 Quality and Scrap Tracking

Link defects to product lines, lots, and operators

Dashboards surface new quality issues in real time

Proactive root cause investigation, fewer rejects

4.4 Inventory and Demand Forecasting

Blend ERP data (stock, orders, lead times) with MES cycle times

Build forecasts that drive purchase decisions

Reduce stock build-ups and supply gaps

4.5 Sales-to-Operations Connection

Combine CRM order velocity with production performance

Surface late or at-risk orders

Improve customer satisfaction and internal coordination

5. Case Studies of DaaS in Action

Industrial Parts Manufacturer

Implemented DaaS across ERP and MES

Reduced manual reporting time by 70%

Cut downtime by 25% in first 6 months

Automotive Supplier

Used DaaS to pilot predictive maintenance

Captured $250k in avoided breakdowns

Saved further through inventory reductions

Food & Beverage Processor

Rolled quality insights into daily dashboards

Reduced scrap by 15% and cut quality investigation time by 50%

6. ROI Made Simple with DaaS

With monthly subscription pricing:

Fast payback — often 12 to 24 weeks

Predictable costs — no platform fees, no data engineers

Outcome-focused — you pay for insights, not infrastructure

7. What to Expect from a DaaS Engagement

Discovery: Audit systems and data maturity

Data Pipeline Setup: Automate extraction, transformation, load

Dashboard Design: Choose metrics aligned to business goals

Pilot Phase: Rollout to one business area for validation

Expand & Train: Scale to wider teams and build internal ownership

Frameworks such as lean data governance and agile pilots ensure buy-in, and impact.

8. Overcoming Your Internal Barriers

Data trust issues – addressed via clear definitions and dashboards

Budget concerns – DaaS starts lean and delivers early wins

Technical gaps – no need for internal engineers; service is fully managed

Change resistance – dashboards are built for day-to-day users

9. How to Start Today

Run an Initial Data Audit

Map your systems, review reporting issues and uncover quick wins

Pilot Your First Dashboard

Pick one area, like OEE or inventory, within 4 weeks

Track ROI and feedback

Measure time saved, cost avoided and engagement

Scale Gradually

Roll out use across other teams driven by the initial pilot success

10. Why DaaS Is a Game-Changer for Mid-Market Manufacturers

Quick ramp-up time, real results in weeks

Flexible spending, with no surprise costs

Immediate visibility, using your existing systems

Continuous improvement, tied to business impact

Future ready, with everything ready for AI or BI down the line

Final Word

Manufacturing isn’t just about hardware anymore. Real competition is data-driven operations, smarter maintenance, and faster decisions. DaaS arms you with that advantage, without heavy investment or tech overhaul.

If you're ready to explore what DaaS could mean for your business, book an Initial Data Audit today with Pentify Insights. It’s your simplest, smartest step toward unlocking the data you already own.